Technologies

Material

Leading the Way for Future Mobility by Innovation

We aim to create the ideal car-oriented society.

The automotive industry is currently facing an unprecedented paradigm shift summed up by the “CASE” acronym (connected, autonomous, shared & services, and electric). With our contributions to this trend, we are actively helping to shape the future. Our goal is to create a society that provides safety, sustainability, and comfortable mobility.

Advancing Value Through Innovation

Since our founding in 1929, the Sumitomo Riko Group has supported the automotive industry with high-quality anti-vibration rubber and hoses. Today, we are focused on autonomous and electric mobility concepts, and are driving innovations for a better future. In doing so, we are contributing to society in terms of safety, comfort and the environment, particularly centered around the “autonomous” and “electric” aspects of CASE.

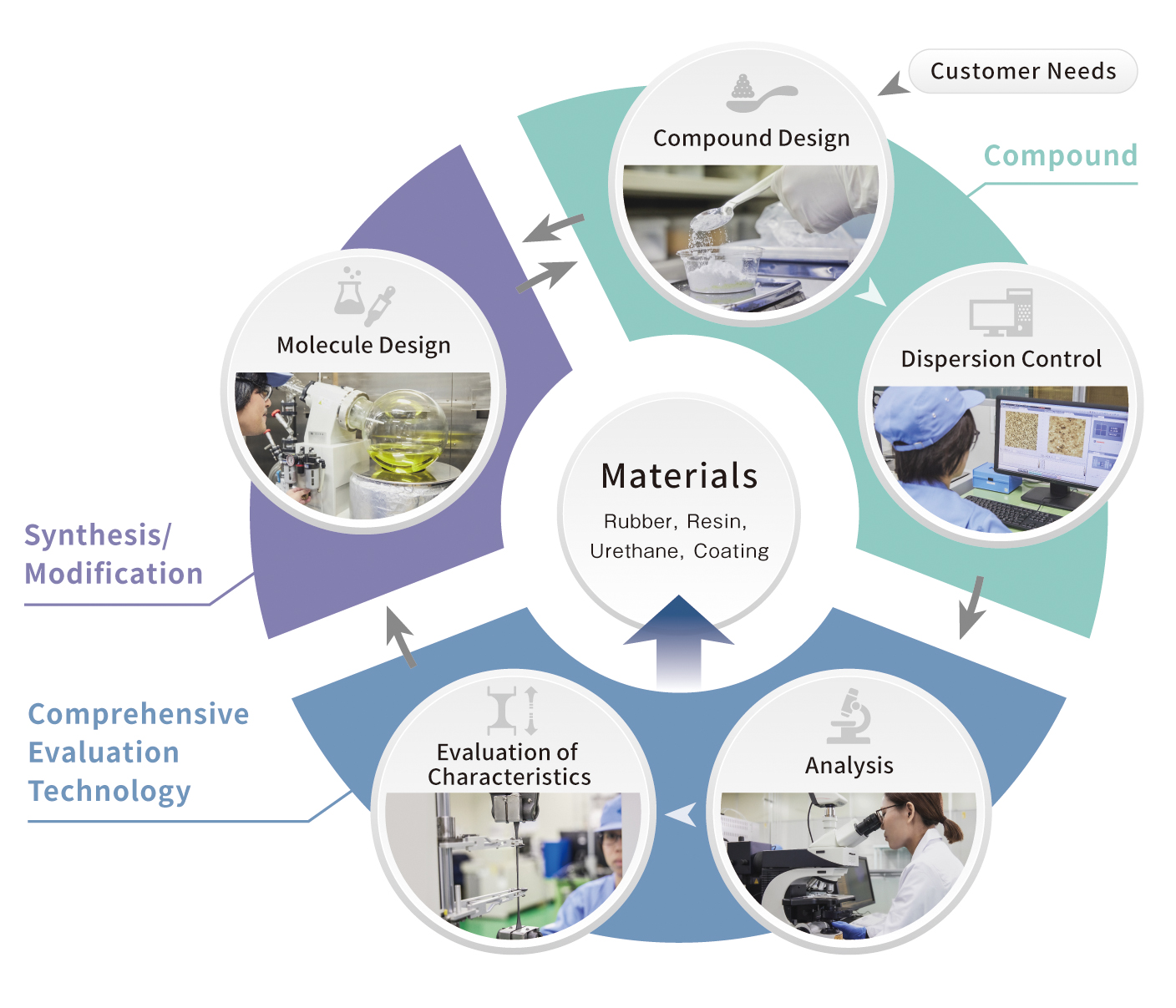

Our Development Process for Polymer Materials

Innovation You Can Feel

The extent to which vibration and noise is reduced has a significant effect on vehicle comfort, no matter the type and size of the vehicle. With its innovative system solutions, SumiRiko AVS makes a key contribution toward a vehicle’s subjective driving characteristics.

However, new vehicle concepts require new solutions, too. The Sumitomo Riko Group’s highly specialized global development teams rise to these challenges. Time and again, the search for technologies that make cars more attractive for end customers results in innovations you can feel.

New Challenges in Future Mobility

SumiRiko AVS is prepared for the evolving challenges of electric mobility and has extensive expertise in adapting to the specifications.

Without the noise of a combustion engine, the natural frequencies of vibration dampers now focus on the 200–1,000 Hz range. Our state-of-the-art electrodynamic shakers enable precise testing with minimal excitation amplitudes and acceleration forces, allowing us to accurately characterize, develop, and industrialize vibration dampers and aggregate mountings.

Our Expertise

With extensive experience in NVH (noise, vibration, harshness) and vehicle dynamics, we are your trusted partner for comfort, safety, and performance. Continuous advancements in technology and production make us a strong engineering ally for future automotive solutions. From design concept to series production, we support our customers with innovation and expertise-trusted by OEMs and top-tier suppliers worldwide.

Modern Testing Facilities

To ensure the performance and durability of our products, SumiRiko AVS operates its own advanced test centers. Our modern facilities can simulate and conduct all standard customer test scenarios.

Continuous expansion and close collaboration between our test engineers, developers, and customers enable us to enhance product reliability and efficiency. With our deep expertise in testing, we guarantee optimal comfort, safety, and dynamics.

CAE Tools

Computer-aided engineering (CAE) has transformed the development process, replacing traditional methods with powerful simulations for faster, more predictive results. Using industry-leading CAD tools, our engineers create complex simulations to optimize NVH performance.

Process Development

The reference system for process development is our shared company philosophy. It forms the basis for our worldwide production and guarantees global quality and process efficiency.

- It conveys a comprehensive vision of core processes at SumiRiko AVS and how they can be improved on an ongoing basis.

- It provides a structured approach for achieving our vision.

- It includes tools and methods designed to help all SumiRiko AVS staff contribute to the success of the group.